Smart Floor Scanner

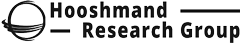

Model: BLUE WOLF X1

The storage tank should regularly be inspected to ensure health. A quick remedial act at an early stage is essential to avoid the future extra cost. Practical inspection recognizes the failure before the leakage, or another failure occurs, preventing leakage of contaminants in the environment, product loss, or even catastrophic failure.

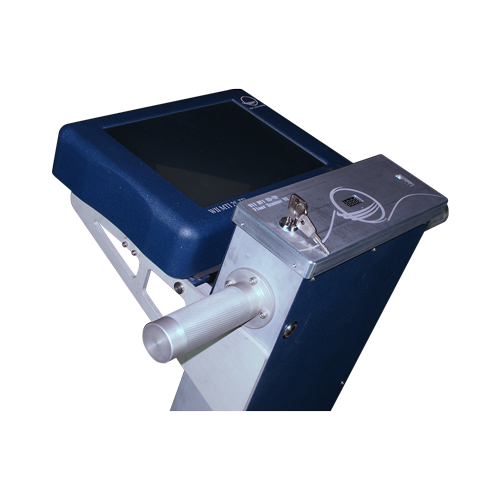

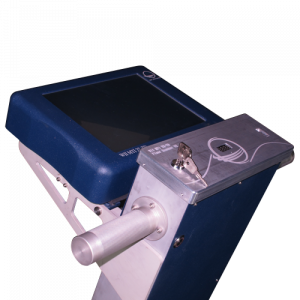

Smart Floor Scanner is a non-destructive tool based on magnetic flux leakage (MFL) principles, which designed to inspect the metallic floor storage tanks for the locations, dimensions, depths of corrosion and defects above and under the surface. Smart Floor Scanner is auto-motorized, allows the inspector to scan the floor of the tank very fast. Also, Smart Floor Scanner equipped with a high-performance PC and specialized software for real-time analysis and display of defects and corrosion data simultaneously. Powerful magnets and sensors located in the form of special arrangements to detect and classify the corrosion and defects in the floors with different thicknesses accurately. Therefore, Smart Floor Scanner can effectively detect corrosion, pitting, and other failures in high resolution. It has benefited:

- High Durable and Powerful Magnet

- High accuracy data acquisition

- Special signal processing by WII algorithms

- Smooth auto-motorized mechanism drive

- Detachable structure for easy handling and transportation

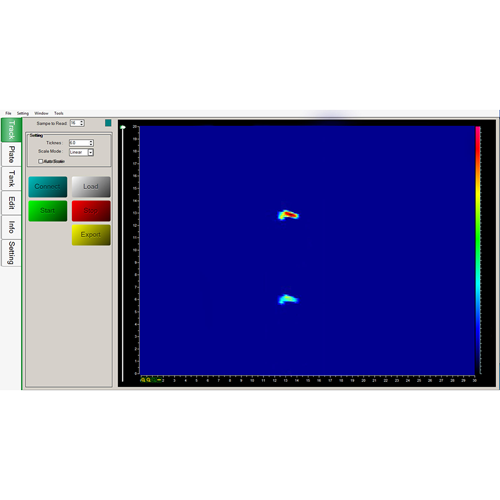

- Professional Smart Floor Scanner Software (SFS)

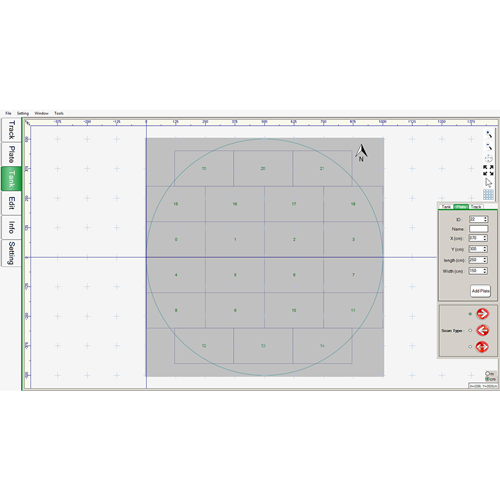

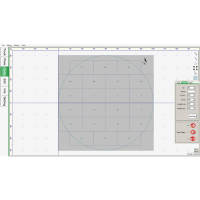

Together these features have led to achieve high-quality inspection and to reduce the inspection time and cost. As a result, the tank’s owner can plan an optimum repair map and improve Fitness For Service (FFS) assessments, Remaining Life Assessment (RLA), and Risk-Based Inspection (RBI) programs. WII software has a user-friendly interface to define the map of plates in the tank. Also, it can modify the inspection data manually by data from other methods (MFL Hand Scanner, UT based, Vision-based, etc.). A special Technical Report Generator implemented on the software.

- Inspect Storage Tank floor and any suitable plate

- Fast Setup & Easy Operation

- Magnetic sensors

- High durable and Powerful magnet

- Special signal processing and defect-recognition by WII algorithms

- User-friendly Software via Touch Screen Computer

- Software-based calibration for different plate thickness

- Chargeable Battery Power

- High-speed inspection by Auto-motorized up to 0.5m/sec

- Online inspection demonstration at Color TFT 12.1”

- Store/Load and manage the reports

Generate Standard/Special Report

Full version - Unlimited user

Free Update & Remote Support